Design and development 2-D/3-D nanostructured materials for biomedical applications

Received: 03-Aug-2017 Accepted Date: Aug 05, 2017; Published: 05-Aug-2017

Citation: Razali MH, Ismail NA, Amin KAM. Design and Development 2-D/3-D Nanostructured Materials for Biomedical Applications. J Microbiol Biotechnol Rep. 2017;1(1):3.

This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http://creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com

Editorial

Currently, we are working on development of 2-D and 3-D materials of TiO2 nanomaterials embedded into biopolymers for biomedical application. TiO2 nanomaterials in particular, nanoparticles, nanowires, nanorods and nanotubes is synthesized using hydrothermal method. Hydrothermal method offers many advantages of energy conservation, simple preparation, rapid reaction, and low operation temperature and cost. The hydrothermal method is conducted through an aqueous process, enabling satisfactory solubility, uniform dispersion of doping metal-ions, and control of stoichiometry. Hydrothermal treatment was used to change the morphology, microstructure, and phase composition of materials by varying the reaction parameters such as temperature and pressure.

For fabrication of 2-D or 3-D materials, gellan gum (GG) biopolymer was used as matrix. Gellan gum is a linear anionic polysaccharides types that produced from fermentation of Pseudomonas elodea. It is consists of a repeating unit of tetrasaccharide: 1,3-linked β-D-glucose, 1, 4-linked β-D-glucoronic acid, 1,4-linked β-D-glucose, and 1,4-linked α-L-rhamnose containing one carboxyl side group. The gellan gum exist in two forms, which are acetylated and deacetylated, being latter the most common and commercially available form. Both form thermo reversible gels, varying in their mechanical properties from soft and elastic for the acetylated form to hard and brittle for the fully deacetylated polysaccharide. They can form a gels in the presence of cations, however, the bonding ability of the ions can be interfere in the presence of acetylated group. GG has been used intensively in the food industry and for culinary practice in Japan and United States since 1988. In fact, GG has been approved as a safe food additive by the United States Food and Drug Administration (US FDA) and the European Union (it is labelled as E 415 in EU regulation).

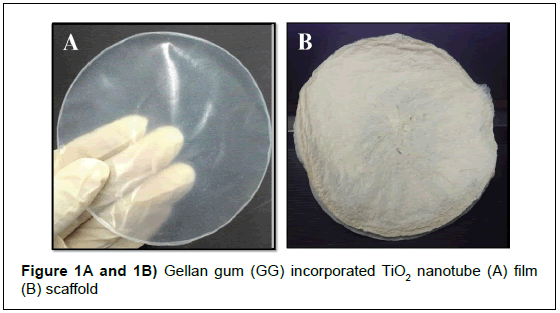

In combination of TiO2 nanomaterials and GG biopolymers, our research group focuses on development of 2-D films and 3-D scaffolds. TiO2 nanomaterials incorporated GG films and scaffolds is synthesised using solvent-casting and freeze-drying methods respectively. Production and characterization of various TiO2 nanomaterials (nanoparticles, nanowires, nanorods and nanotubes) on physical, chemical and biological properties of films and scaffolds is investigated. On top that new formulations using another nanomaterials and biopolymers have been designed and produced to full filled the requirement of ideal biomaterials for tissue engineering and wound dressing (Figure 1).

Figure 1A and 1B: TiO2 nanoparticles incorporated GG film and scaffold.

At this moment, we have successfully fabricated TiO2 nanoparticles incorporated GG film and scaffold. The fabricated film and scaffold was characterized using fourier transform infrared (FTIR), x-ray diffraction (XRD), scanning electron microscopy (SEM), atomic force microscopy (AFM) and termogravimetric/ differential thermal analyzer (TG-DTA) to study their physicochemical properties. The mechanical properties of film and scaffold was studied using an Instron Universal Testing machine (model 3366) with a load capacity ±10 kN grips and cross-speed set at 10 mm min-1. Water Vapour Transmission Rates (WVTR) and swelling was measured using American Society for Testing and Materials (ASTM) International Standard method. Meanwhile, the biological properties such as antibacterial of film and scaffold was observed qualitatively and quantitatively. Gram-positive (Staphylococcus aureus and Streptococcus) and gram-negative (Escherichia coli and Pseudomonas aeruginosa) microbes was for an anti-bacterial assay. Last but not last least, in-vivo and in-vitro cell studies using fabricated film and scaffold was carried out. The example of in-vivo study is excision wound model. In this method, the rats were anaesthetized by inhalation of diethyl ether and their paws was tied to boards. An 8 mm wound was created using sterile wound bio-puncher. The measurement of the wound area was carried out from the day of the excision of the wound and at every three (3) days interval until the epithelisation of the wound was completed. On the other hand, in-vitro study of cell proliferation was quantified using a MTT (3-(4,5-dimethylthiazol- 2-yl)-2,5-diphenyltetrazolium bromide). Commonly used cells are 3T3 mouse fibroblast, human skin fibroblast and etc.