Design of Hierarchical Nano-structure for Multifunctional Applications

Received: 16-Nov-2017 Accepted Date: Nov 17, 2017; Published: 23-Nov-2017

Citation: Xian SH, Xiaoqiao HE. Design of Hierarchical Nano-structure for Multifunctional Applications. Nanotechnology Letters. November-2017;1(1):6.

This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http://creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com

In the practical application of a material, different properties are anticipated to realize various functions. Instead of achieving a specific function, multifunctional materials are much more preferred, but it used to be a challenge for most materials to achieve a multifunction integration. However, with the development of nanotechnology, scientists try to figure this problem out based on the relationship between the properties of a material and its micro- or Nano-structure. On the one hand, experimental approaches keep progressing to achieve desired control of the material nanostructure during the fabrication process. On the other hand, computational simulations assist to predict the possible properties based on the structure design of the material. Our recent work reveals the design potentials of the radial shrinkage of a hierarchical tubular structure, which named super carbon nanotube [1].

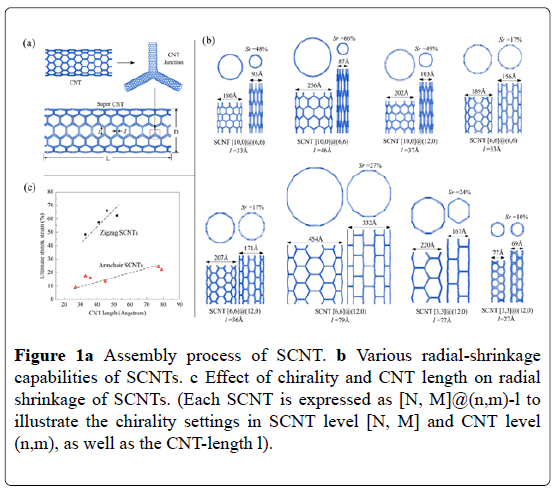

Super carbon nanotube (SCNT) [2] is a covalent network fabricated through the hierarchical assembly of carbon nanotubes. It possesses the same topology of CNTs (Figure 1).

Figure 1: a. Assembly process of SCNT. b. Various radial-shrinkage capabilities of SCNTs. c. Effect of chirality and CNT length on radial shrinkage of SCNTs. (Each SCNT is expressed as [N, M]@(n,m)-l to illustrate the chirality settings in SCNT level [N, M] and CNT level (n,m), as well as the CNT-length l).

Several kinds of CNT-based covalent networks were proposed in order to obtain robust interactions and overcome the disordered distribution of bulk CNTs. However, the hierarchical structure makes SCNT distinguished from other CNT-based structures. This assembly strategy is very common in biological system, like nacre, and has been reported to be the major contribution of some extraordinary properties, such as self-healing and multi-functionality. The superior features of SCNTs have also been reported, such as super tensile flexibility with competitive strength as CNTs and outstanding capabilities of force transferring.

In our study, we focus on the designable radial performance of SCNTs. Since CNTs have been widely applied for medicine delivery and Nanotransportation because of the channel characteristic. With the similar tubular structures, SCNTs could also serve as the channels of molecular delivery, especially for the large diameter cases. Moreover, the hierarchical structure may enable SCNTs to have more distinguished properties than CNTs when serving as channel structures.

Classical molecular dynamic simulations are conducted to explore the radial deformation characteristics of SCNTs. From Figure 1a, it can be seen that the chirality (arrangement of CNTs in a SCNT) and CNT length are two important parameters determine the geometric structure of SCNTs. Hence, SCNTs with different chirality and CNT-length settings are constructed and presented in (Table 1). Note that SCNTs have two-level chirality settings due to the hierarchical structure. The detailed information for the molecular dynamic simulations can be obtained in our recently published paper [1].

| SCNT Models | Chirality type | CNT Length (Å) | D0(Å) | Reversible Range (%) | Sr (%) |

|---|---|---|---|---|---|

| [10,0] at (6,6)-33Å | Zigzag-Armchair | 33 | 180.01 | 44.07 | 48.46 |

| [10,0]at(6,6)-46Å | Zigzag-Armchair | 46 | 255.60 | 48.74 | 66.14 |

| [10,0]at(12,0)-37Å | Zigzag-Zigzag | 37 | 201.59 | 37.03 | 49.23 |

| [6,6]at(6,6)-33Å | Armchair-Armchair | 33 | 189.42 | 30.13 | 17.45 |

| [6,6]at(12,0)-36Å | Armchair-Zigzag | 36 | 207.01 | 24.01 | 17.23 |

| [6,6]at(12,0)-79Å | Armchair-Zigzag | 79 | 454.24 | 24.44 | 26.98 |

| [3,3]at(12,0)-27Å | Armchair-Zigzag | 27 | 76.52 | 24.36 | 9.80 |

| [3,3]at(12,0)-77Å | Armchair-Zigzag | 77 | 219.99 | 23.34 | 24.24 |

Table 1 Radial deformation and mechanical parameters of SCNTs in this work.

In the work, uniaxial tension is carried out to evaluate the shrinkage deformation in the radial direction of SCNTs. Figure 1b presents the snapshots of each SCNT from the initial state to the final state before fracture, with the illustration of geometric settings and the maximum radial shrink strain . Various radial-shrinkage capacities can be directly observed, ranging from 10% to 66%. Generally, zigzag SCNTs have higher level of radial-shrinkage capacities. For the same chirality types, the radial shrinkages increase with the increasing length of CNTs. However, the sensitivity to the length increment is quite different for different chirality types of SCNTs. The explicit regularity can be seen from Figure 1c that the ultimate shrink strains of SCNTs is proportional to CNT length for both zigzag and armchair SCNTs, but the slope of armchair SCNTs is much lower than that of zigzag SCNTs. Such differences are owing to the diverse rotation stiffness at junctions caused by the different hierarchical structures. In addition, SCNTs are found to have prominent reversibility within considerable deformation ranges, which depends on the appearance of the Stone-Wales defects. Based on the critical point of defects, reversible ranges of each SCNT can be determined.

By adopting the geometry design of the hierarchical structure, radial shrinkages of SCNTs can be adjusted in a considerable range. Such structure-dependent properties will broaden the application prospects of SCNTs. Zigzag SCNTs with super radial flexibility are competitive to serve as switches in the Nano-transportation system. Through strain control in the axial direction, the transformation between different radial sizes will achieve the function of material screening and filtration. As for armchair SCNTs with limited radial deformation, they are valuable for the cases in which the excessive deformation should be avoided when subject to various external disturbances. Under such cases, SCNTs can provide robust support to ensure the normal Nano-transportation.

Considerable breakthrough has been fulfilled for nanotechnology as well, from controllable covalent connection to synthesis of complex hierarchical structures. Hence, there are sufficient reasons to believe that the practical application of the nanostructure design is just around the corner.

REFERENCES

- Shi X, He X, Wang L, et al. Hierarchical-structure induced adjustable deformation of super carbon nanotubes with radial shrinkage up to 66%[J]. Carbon, 2017;125: 289-98.

- Coluci VR, Galvao DS, Jorio A. Geometric and electronic structure of carbon nanotube networks:‘super’-carbon nanotubes[J]. Nanotechnology 2006;17:617.