Design of Shape Memory Hybrid with Water-assisted Healing Function

Received: 13-Sep-2017 Accepted Date: Sep 28, 2017; Published: 06-Oct-2017

Citation: Wei Min Huang. Design of Shape Memory Hybrid with Water-assisted Healing Function. J Nanoscience and Nanomedicine. September-2017;1(1):3

This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http://creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com

Design of Shape Memory Hybrid

Self-healing is meant for automatic repairing, so that a piece of damaged material regains its original properties, and consequently its service life time is extended. Ideally, the material should have the capability to sense the damage and subsequently to react by means of repairing accordingly. However, most of the so-called self-healing materials reported so far are essentially a kind of stimulus-assisted healing, in which self-sensing function is missing and an external stimulus is required for healing.

From engineering point of view, a healed piece of material should meet as many as possible the following requirements [1],

1) Shape recovery

2) Strength recovery

3) Instant recovery

4) Repeat recovery

1) Can be achieved via the shape memory effect (SME) [2], which refers to the phenomenon of shape recovery in a piece of severely deformed material, but only at the presence of the right stimulus. 2) and 4) may be achieved by a kind of re-bonding mechanism when the right stimulus is applied. 3) Is actually very much dependent on the type of applied stimulus to trigger re-bonding.

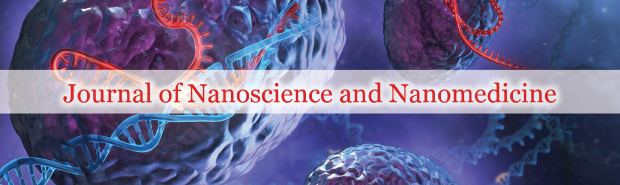

In Wang et al. [1] study, a shape memory hybrid (SMH) made of silicone and melting glue has been demonstrated to have the heat-assisted healing function. According to the definition of SMH of Huang et al. [2], a piece of SMH has at least two components, one component is always elastic to store elastic energy once the hybrid is deformed into a temporary shape (a process technically called programming), and the other component (transition component) has the capability to switch between hard and soft (easy to plastically deform) depending on whether the stimulus is presented. In the case of above mentioned silicone/melting glue hybrid, the silicone serves as the elastic matrix and melting glue is the transition component. Since upon heating to high temperatures, melting glue becomes easy to flow and in the meantime, it can serve as glue to bond two separate surfaces together, this SMH intrinsically has the heat-assisted healing feature, and meets all four requirements for effective healing mentioned above. This heat-assisted concept via hybrid is demonstrated in Figure 1, using an elastic sponge/wax SMH. The SMH sample is prepared via letting hot liquid wax absorbed by an open cell elastic sponge. After cooling, solid wax occupies the pores in the sponge. Two pieces of such a SMH can be heated and bonded together to achieve heat-assisted healing.

Based on the same working mechanism, we may design a SMH for chemo-assisted healing, i.e., healing can be realized upon applying a particular chemical/solvent. A simple example of water-assisted healing is presented here to demonstrate the basic concept. A kind of nanofabrication technology is applied in the fabrication of the SMH.

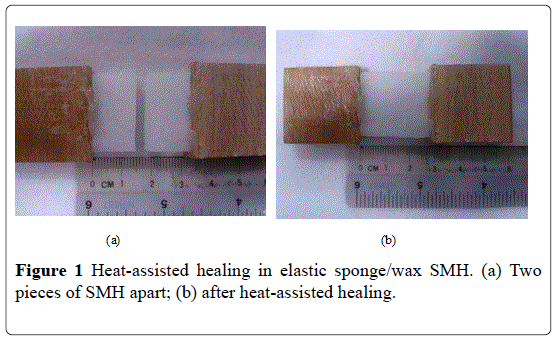

In Figure 2a, a piece of dry hydrogel (same type as used in Zhang et al. [3]) is cut by a sharp blade for a line on its one side for about 2 mm deep. After immersing in room temperature water (about 22 ˚C) for a few minutes, water penetrates into the hydrogel from its surface inward (Figure 2b). Significant swelling upon wetting causes wrinkling on the surface of the hydrogel [3]. After drying, the piece of hydrogel regains its original shape. However, the line-crack remains, but becomes less visible (Figure 2b). The closure of the crack is due to water-activated SME as well discussed in Zhang et al. [3]. However, since the crack is still there, its strength is not recovered. Another material, which is responsive to water, is required to bond the broken surfaces.

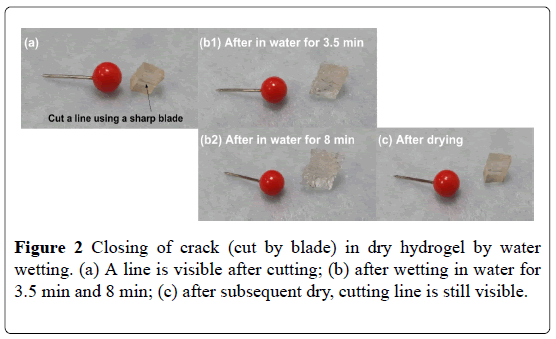

In Figure 3a, a tooth pick is penetrated through a piece of wet SMH made of the same hydrogel (as used in Figure 2) and hydrogel-polyethylene glycol (PEG). Refer to as reported in Zhang et al. [3], the dry for details of this SMH is produced in the following three steps;

1). PEG is dissolved in water;

2) Dry hydrogel is immersed in PEG solution for full swelling;

3) Dry PEG.

For wet SMH as shown in Figure 3a, the fabrication process stops after Step 2). In Step 2), the dry hydrogel swells upon wetting significantly, and Nano sized PEG particles, which are dissolved in water, penetrate into the hydrogel network.

After removal of the toothpick, the hole gradually shrinks during drying in air, and finally a small indent is left (Figure 3b). Although Since the wet hydrogel is rather brittle, so that the penetration of toothpick causes a permanent hole in it, and PEG serves as filler to fill and close the hole.

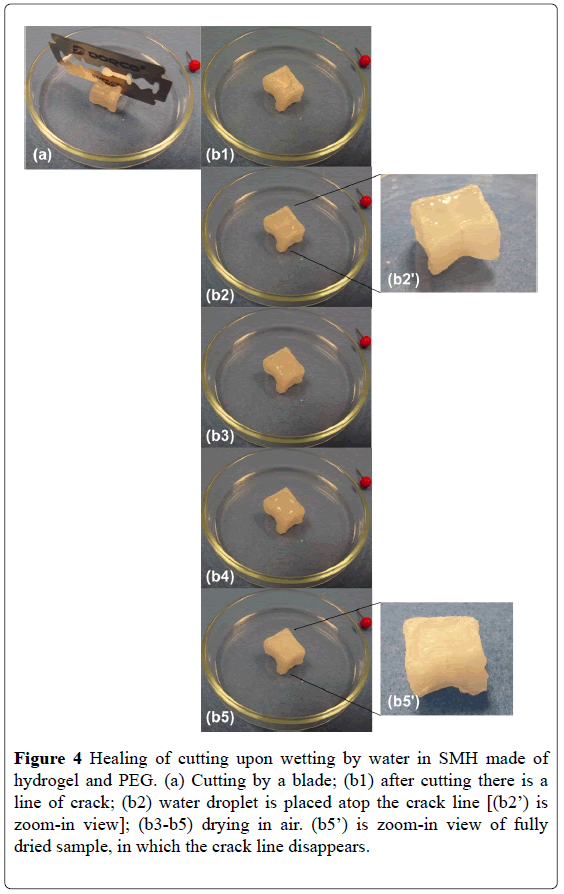

Now, it becomes obvious that the dry hybrid should have the water-assisted healing function. As revealed in Figure 4a, a 2 mm deep of line is cut by a sharp blade on a piece of dry SMH. Subsequently, a water droplet is placed atop to heal the crack. After the SMH is dried again, the crack disappears. PEG effectively re-bonds the sample and heals the crack.

Figure 4: Healing of cutting upon wetting by water in SMH made of hydrogel and PEG. (a) Cutting by a blade; (b1) after cutting there is a line of crack; (b2) water droplet is placed atop the crack line [(b2’) is zoom-in view]; (b3-b5) drying in air. (b5’) is zoom-in view of fully dried sample, in which the crack line disappears.

Above example demonstrates a simple approach to design a SMH for water-assisted healing. Nano-sized PEG particles dissolved in water penetrates into hydrogel during its wetting process. The absorbed PEG later on serves as the bonding material upon wet/dry cycling to heal the sample. Here, we only focus on shape recovery, while instant recovery and repeat recovery are obvious. Strength recovery, in particular upon tension, is under investigation right now. Same concept may be extended to other chemoresponsive SMHs or shape memory polymers to achieve chemo-assisted healing.

REFERENCES

- Wang CC, Huang WM, Ding Z, et al. Rubber-like shape memory polymeric materials with repeatable thermal-assisted healing function. Smart Mater Struct. 2012;21.

- Huang WM, Ding Z, Wang CC, et al. Shape memory materials. Mater Today 2010;13:54-61.

- Zhang JL, Huang WM, Lu HB, et al. Thermo-/chemo-responsive shape memory/change effect in a hydrogel and its composites. Mater Des. 2014;53:1077-88.