Nucleation and Growth of Silicon Quantum Dots

Received: 07-May-2021 Accepted Date: May 17, 2021; Published: 27-May-2021

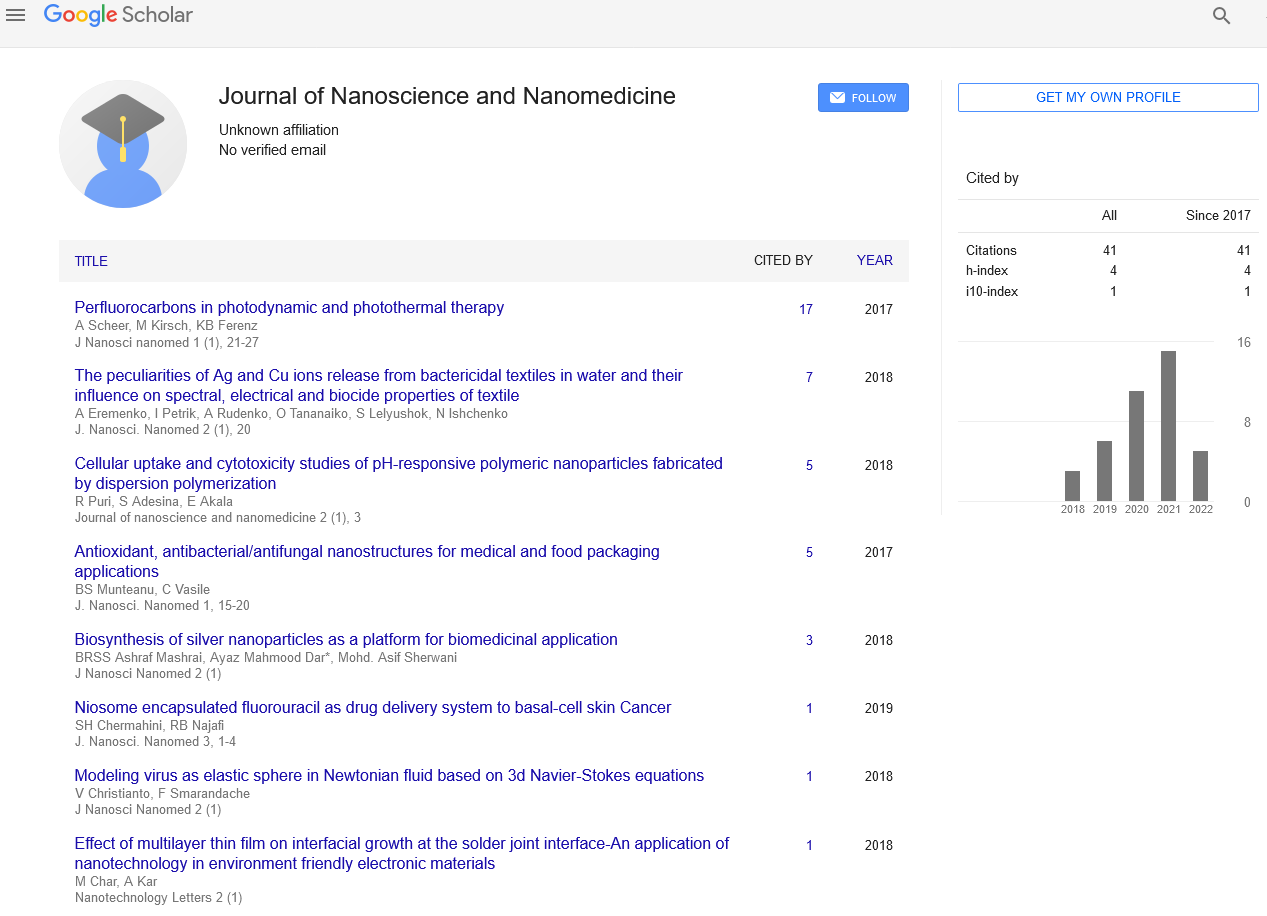

Citation: Gorati S. Nucleation and Growth of Silicon Quantum Dots. J Nanosci Nanomed 2021;5(3):4.

This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http://creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com

Introduction

An investigation of nucleation and development of Si quantum specks on SiO2, SiOxNy and Si3N4 substrates utilizing silane low pressing factor compound fume testimony (LPCVD) at low temperature (570–610°C). The examples are explored by nuclear power micoscopy (AFM), checking electron microscopy (SEM), high goal transmission electron microscopy (HRTEM) and spectroscopic ellipsometry (SE). A modestly low temperature (≤800 °C) warm handling procedure has been depicted for the development of the silicon quantum spots (Si-QD) inside microcrystalline silicon carbide (μc-SiC:H) dielectric slim movies stored by plasma upgraded compound fume statement (PECVD) measure [1].

Quantum spots have properties halfway between mass semiconductors and discrete iotas or atoms. Their optoelectronic properties change as a component of both size and shape. Bigger QDs of 5–6 nm measurement emanate longer frequencies, with tones like orange or red. Quantum specks (QDs) are man-made nanoscale precious stones that that can move electrons. At the point when UV light hits these semiconducting nanoparticles, they can transmit light of different shadings. These counterfeit semiconductor nanoparticles that have discovered applications in composites, sun powered cells and fluorescent organic marks. Nanocrystals in which purported quantum impacts happen because of their tiny measurement (in the scope of a couple of nanometers) are called quantum specks. These don't comprise of a uniform material, however depict a whole class of materials [2].

A quantum spot show is a showcase gadget that utilizations quantum specks (QD), semiconductor nanocrystals which can create unadulterated monochromatic red, green, and blue light. This innovation is utilized in LED-illuminated LCDs, however it is material to other showcase advancements which use shading channels, like blue/UV OLED or MicroLED. This show that the substance idea of the surface, definitely, the presence of SiO bonds [3], diminishes the Si quantum dab thickness. By enhancing the statement boundaries, a Si speck thickness of 1012 cm−2 can be acquired beneath 600°C on an unadulterated Si3N4 surface. The impact of hydrogen, given by silane disintegration, on the Si nucleation component will be talked about. To be effectively coordinated in nanohardware gadgets, silicon quantum spots (Si-QDs) thickness, thickness consistency, size and size scattering should be controlled with an incredible exactness. Nanometric size Si-QDs can be kept on covers by SiH4 CVD. Their development incorporates two stages: nucleation and development. We study the test boundaries which impact each progression to improve the control of the Si-QDs morphology [4].

Optoelectronic sensors change over light of different wavelengths into an We show that the nucleation step is administered by the reactivity of the substrate with the Si antecedents. On SiO2, OH bunches are distinguished as nucleation destinations. By controlling the OH thickness on the SiO2 surface, we can screen the Si-QDs thickness on over multi decade for a similar cycle conditions. By adjusting the gas stage arrangement, i.e by utilizing SiH2Cl2 as Si antecedent, we can develop the cores previously framed during the nucleation venture without arrangement of new Si-QDs. We talk about the upsides of this interaction to improve the control of the Si-QDs size and breaking point the size scattering [5].

REFERENCES

- Mazen F, Baron T, Hartmann J.M et al. Control of Silicon Quantum Dots nucleation and growth by CVD. MRS Online Proceedings Library. 2002;737:19.

- Tilke AT, Simmel FC, Blick RH, Lorenz H, Kotthaus JP. Coulomb blockade in silicon nanostructures. Prog Quantum Electron. 2001;25(3):97-138.

- Baron T, Martin F, Mur P, Wyon C, Dupuy M. Silicon quantum dot nucleation on Si3N4, SiO2 and SiOxNy substrates for nanoelectronic devices. J Cryst Growth. 2000;209(4):1004-8.

- Kohno A, Murakami H, Ikeda M, Miyazaki S, Hirose M. Memory operation of silicon quantum-dot floating-gate metal-oxide-semiconductor field-effect transistors. Jpn J Appl Phys.2001;40(7B):L721.

- Vansant EF, Van Der Voort P, Vrancken KC. Characterization and chemical modification of the silica surface. Elsevier. 1995;25.