Environmental impact of nanoscale materials

Received: 07-Sep-2021 Accepted Date: Sep 19, 2021; Published: 27-Sep-2021

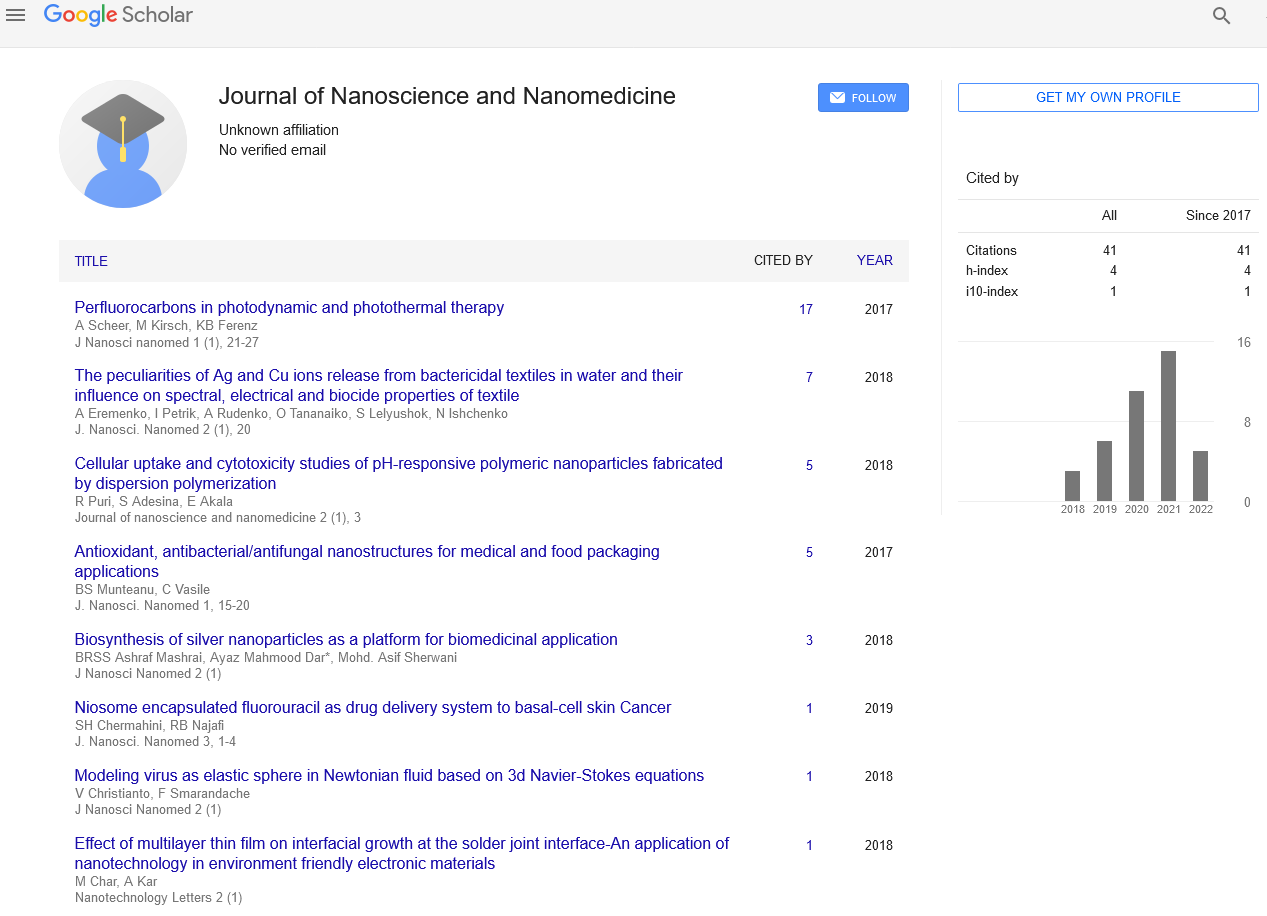

Citation: Francius X. Environmental impact of nanoscale materials. J Nanosci Nanomed 2021;5(5):5.

This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http://creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com

Introduction

Sustainable structural materials with fully bio-based building blocks and great mechanical properties are vitally important for practical application. However, the challenges on how to evitable use petrochemical-based adhesive, improve their comprehensive mechanical strength, and reduce energy and time consumption still remain. Here, we report a robust and effective strategy with micro/nanoscale structure design to fabricate a mechanically strong and sustainable wood-derived structural material from fast-growing wood. Owing to the synergistic effect of aligned cellulose fiber, multi-layer structure, and hydrogen bonds, the obtained structural materials exhibited high mechanical properties of 158 MPa, high interfacial bonding strength of 1.13 MPa, and great Shore D hardness of 68.7. The role of hydrogen bonds in enhancing mechanical properties was also revealed. In addition, the adhesive and polymer are not used in the whole process, and the consumption of energy and time is reduced. The novel fully wood- derived materials provide more structural material selection and more micro/nanoscale structure design ideas [1].

Sustainable structural materials with exceptional performance have sparked widespread interests under the goal of carbon neutrality. Based on the raw material efficiency and environmental benefit, bio-resources materials should be prioritized as building block for constructing sustainable structural materials. However, the limited mechanical performance and excessive reliance on petrochemical-based adhesive put a huge obstacle in constructing structural materials, such as wood-based boards and wood-plastic composites [2].

Micro/nanoscale structure plan invest the macroscale materials tall large scale level execution by tuning the micro/nanoscale interface properties. Due to the multiscale various leveled structure of delignified wood, profoundly adjusted cellulose fiber, and tunable surface physical and chemical properties, numerous cases of moving forward the comprehensive properties of wood-based materials have been effectively realized through this technique. For case, the mechanical quality of wood-derived film has been surprisingly made strides through change over hydroxyl bunches into carboxyl bunches to extend the degree of fibrillation [2]. Recovered isotropic wood was manufactured by small scale structure plan. Profited from different hydrogen bond s and calcium particle cross-linking, it shows great water resistance and fire retardancy properties. Therefore, microscale structure plan may be a vigorous methodology to get ready cost-efficient and maintainable wood-based auxiliary materials [3].

The synergistic effect can be understood from three perspectives. First, from a structure point of view, the most important factor was the density, which was tightly correlated to the mechanical properties. Under the same pressure, CLP exhibited a denser structure and a higher density than DW, which can be calculated through thickness. In outline, a strong and compelling methodology with micro/nanoscale structure plan has been utilized to manufacture high-performance maintainable auxiliary fabric from fast-growing wood. A synergistic impact of cross-laminated structure, cellulose characteristics, and hydrogen bonds arrange is uncovered. The gotten basic materials displayed tall mechanical properties of 158 MPa, tall interfacial holding quality of 1.13 MPa, and awesome Shore D hardness of 68.7. In expansion, the cement and polymer are not utilized within the entire handle, and the utilization of vitality and time is decreased. These comes about give imaginative direction to plan adhesive-free, economical, and ecologically sound bio-based fabric, and grow the plausibility for the utilize of fast-growing wood in basic materials [4].

REFERENCES

- Fu Q, Yan M, Jungstedt D, et al. Transparent plywood as a load-bearing and luminescent biocomposite. Compos Sci Technol. 2018;164(2):296- 303.

- Gang Zhou. Metal/graphene heterobilayers as hydrogen evolution reaction cathodes: a first-principles study. Phys Chem Chem Phys. 2019;21(8):4594-4599.

- Ling S, Chen W, Fan Y et al. Biopolymer nanofibrils: structure, modeling, preparation, and applications. Prog Polym Sci. 2018;85(2):1-56.

- Frey M, Widner JS, Segmehl K. Delignified and densified cellulose bulk materials with excellent tensile properties for sustainable engineering. ACS Appl Mater Interfaces. 2018;10(5):5030-5037.