Optimization of some processing conditions of fortified maize snack (Kokoro) using response surface modeling

2 Department of Hospitality management Technology, School of Technology, Lagos State Polytechnic, Lagos, Nigeria, Email: FashakinJf@yahoo.com

Received: 06-Sep-2017 Accepted Date: Sep 26, 2017; Published: 03-Oct-2017

Citation: Bolaji OT. Optimization of some processing conditions of fortified maize snack (Kokoro) using response surface modeling J Food Drug Res 2017;1(1):11-17.

This open-access article is distributed under the terms of the Creative Commons Attribution Non-Commercial License (CC BY-NC) (http://creativecommons.org/licenses/by-nc/4.0/), which permits reuse, distribution and reproduction of the article, provided that the original work is properly cited and the reuse is restricted to noncommercial purposes. For commercial reuse, contact reprints@pulsus.com

Abstract

This work attempted optimization of processing conditions of fortified kokoro using response surface modeling (RSM). A central composite rotatable experimental design with three factors (frying temperatures, frying time and cowpea proportions) and five levels was used to evaluate some functional properties and consumer acceptability. The result revealed that solubility, swelling capacity and water absorption capacity of maize-cowpea blend decreased with increase in frying time and temperature. The values obtained for bulk density, swelling capacity, solubility, water absorption capacity and oil absorption capacity ranged from 0.46-0.48 g/mL, 1.27-3.37%, 7.77-10.13%, 171.67-213.33% and 146.67-183.33%, respectively. There was significant difference (p<0.05) in the values obtained for texture, crispiness and taste of fortified kokoro. The desirability value for all the responses was approximately 0.64. The research revealed that varying frying temperature and frying time simultaneously have strong tendency to affect the quality of properties of kokoro fortified with cowpea.

Keywords

Optimazation; Maize; Cowpea Snack; Kokoro; FryingIntroduction

There abound many traditional maize based snacks consumed in many parts of Nigeria. These include Kokoro (corn-cake), aadun (maize pudding), donkwa (maize peanut balls) [1]. Kokoro is a traditional snack consumed especially in western parts of Nigeria. Processing conditions and proportion of materials are critical in determining the quality of snacks like kokoro. Kokoro is consumed by categories of people with varying nutritional demands and therefore suggest the need for nutritional enhancement. The outcome of inclusion of nutrient aiding food materials at varying proportion and production conditions may be necessary. The addition of vegetable protein to improve the nutritional value of snacks were reported by some researchers [1-3]. Some researchers reported the quality and nutritional contents improvement of kokoro using beniseed, cowpea, soybean, groundnut and African yam bean [1,4,5]. Several other studies have been carried out to improve the protein quality of maize products by fortification with plant proteins such as cowpea, soybean and groundnuts [1]. These were, however, done without an attempt to optimise the process conditions and proportion.

Deep fat frying is an established process of food preparation [6,7]. It often involves simultaneous heat and mass transfer process. In this process, moisture is reported to leave the food in form of vapor bubbles and oil is absorbed simultaneously. In some cases, it is used mainly to activate unique flavors and texture of processed foods [7,8]. Modification of physical, chemical and sensory characteristics of the food have been reported as possible outcome of this operation. Some researchers reported that temperature and frying time are major variables controlling deep fat frying operation [7,9,10].

In order to maintain the quality, increase yield and reduce or maintain cost of production, optimizing the process is very essential. Optimization is useful in improving the performance of the food system [11]. Optimizing process and procedure have been reported to aid manipulation of multiple variables of fewer experimental trials [11,12]. These often result into developing interactions and models that is capable of aiding efficient and economic production process. This provide experimental methodology that help generate a mathematical model that may favorably describe and predict the process.

The possibility of producing acceptable kokoro with better nutritional content and sensory quality from maize flour mixed with some legumes have been attempted by some researchers [1,3-5,13]. This study attempted the determination of the optimal level of the processing conditions and cowpea proportion inclusion (Frying temperature, frying time and quantity of cowpea) using response surface methodology (RSM), which is rare in previous reported works.

Material and Methods

Maize cultivar (ART 98| SW6-OB) was obtained from Institute of Agricultural Research and Training in Ibadan, Oyo State, Nigeria. Cowpea was obtained from Sabo market, Ikorodu, Lagos state, Nigeria. Refined vegetable oil, salt, onions were obtained from Sabo, Ikorodu, Lagos State. The maize grains and cowpea were sorted, washed, dehulled manually, sun-dried and milled using attrition mill (TYPE YL: 112M–4, ATLAS EXCLUSIVE ALZICO LTD). A deep fat fryer (Model MC-DF 1031) was used for frying Kokoro. The maize-bean flour blends proportions were produced according to Box Behnken experimental design of Response Surface as shown in Table 1. These various blends were packed separately in 100 μm polythene bags and kept in airtight plastic containers till needed. Half of each blend was mixed and stirred in boiled water to make a paste and the remaining half was mixed with salt and onion and then added to the paste with continuous stirring for about three minutes to form homogenous thick dough [1,3,14]. The dough was cooled and kneaded. The kneaded dough was cut into sizes and rolled into ring shapes as generally practiced with the aid of a chopping board. These rolled out pieces were deep-fried in hot refined vegetable oil at temperature between 130, 140 and 150°C and frying time 4, 7 and 10 min, respectively. These were achieved in the combination using a deep fryer for all round frying. The fried pieces of maize-cowpea snacks with the deep fryer equipment (Model MC-DF 1031) were drained and left to cool. The proximate, functional and pasting analyses were conducted on the blends while the consumer acceptability test was determined on the fried kokoro [15].

TABLE 1 Coded values of the independent variables

| -α | -1 | 0 | 1 | +α | |

|---|---|---|---|---|---|

| X1 (°C) | 136.46 | 130 | 140 | 150 | 143.54 |

| X2 (Min) | 5.94 | 4 | 7 | 10 | 8.06 |

| X3 (%) | 92.03 | 90 | 95 | 100 | 97.97 |

| α=1.4142 X1=Frying Temperature X2=Frying Time X3=Maize Proportion. |

|||||

Experimental Design and Modelling for Optimization

A central composite design with three factors and levels were used. The three independent variable factors used were frying temperature (X1), frying time (X2) and beans proportion (X3) and the dependent variable responses were bulk density, swelling capacity, solubility, water absorption capacity, oil absorption capacity and the sensory evaluation parameters (taste, aroma, texture, overall acceptability, colour and crispiness) and the pasting properties were determined. Twenty frying trials were performed with eleven central points. The coded value of the independent variables and treatment schedule are as reported in Table 1.

Determination of Functional Properties

Bulk density determination

The procedure of Narayana and Narasinga [15] was used with slight modification in the determination for bulk density. The bulk density was computed as shown in Equation 1.

BULK DENSITY=W/M (1)

Swelling power and solubility

The swelling power and solubility of the maize-based flour samples were determined using the method reported by Leach et al. [16]. A 1 g of Maize-based flour was weighed into centrifuge tube and 50 mL distilled water was added. These tubes were immersed in water bath for 30 minutes, thoroughly and constantly stirred with glass rod during the heating period. The tubes were removed, cooled to room temperature and centrifuged at 500 rpm for 15 minutes. The supernatant was fully transferred into a conical flask and 5ml was pipetted into a weighed petri dish, evaporated over a steam bath and dried in the air oven at 105°C for 4 hours. The weight of the pastes were determined and used to calculate the swelling power as gram of sediment paste per gram maize based flour. Percentage solubility was calculated as gram per gram maize-based flour.

Water and oil absorption capacities

Oil and water absorption capacities were determined, employing the method described by Beuchat [17] and a 10 mL of distilled water or oil was added to 1 g of sample. The mixture was mixed thoroughly for 30 seconds and allowed to stand for 30 min. The volume of the supernatant was recorded. The mass of oil or water absorbed were expressed in percentage.

Sensory evaluation of fortified maize snack (kokoro)

Quality attributes of the kokoro made from maize and beans flour against a whole maize snack (kokoro) were assessed by 20 member panellists using 9 point Hedonic scale with respect to taste, aroma, texture, colour, crispiness and overall acceptability. The scores were ranked and subjected to statistical analysis.

Model development

Response surfaces were represented mathematically by second-order polynomial equation to determine the relationship between dependent variables and independent variables. The model proposed for the response (Yi) as shown in eqn. [2]

Yi=b0+b1X+b2X2+b3X3+b11X12+b22X22+b33X32+b12 X1 X2+b13 X1 X3+b23 X2X3 ………(2)

Where X1, X2 and X3 are frying temperature (°C), frying time (min) and cowpea proportion (%), respectively. b0 is the value of the fitted response at the centre point of the design (i.e., regression coefficient for interception), b1-b3, b11-b33 and b12-b23 are regression coefficients for linear, quadratic and interaction (i.e., cross product terms), respectively. Y (i=8) is the predicted responses for bulk density, swelling power, solubility, water absorption capacity, and oil absorption capacity, respectively [18]. In order to effectively confirm the adequacy and accuracy of the fitted models, analysis of Variance (ANOVA) was performed. The use of desirability function of RSM that combine all responses into one measurement was also employed [18].

Result and Discussion

The bulk density is generally affected by the particle size and had been reported to have relevant application on packaging, transportation, raw material handling. The quadratic model with R2=0.55 described the changes in bulk density of maize-cowpea blends snack (kokoro) during frying as shown in Table 2. The bulk density of the kokoro ranged from 0.46-0.48 g/mL and there was significant difference (p<0.05) among the samples as reflected in Table 3. Similar trend was reported by Abegunde et al. [5]. According to Fasasi et al. [19] the bulk density may be affected by protein sources and level of supplementation. According to study in 2008, Bulk density of food is very relevant in packaging. The result revealed that there was significant difference (p<0.05) for Swelling capacity which ranged from 1.27% to 3.37%. The swelling capacity obtained was in agreement with values reported by Abegunde et al. [5] and in contrary to values reported by Ayinde et al. [4]. In this research work, swelling Capacity decreased with increase in cowpea proportion.

TABLE 2 Experimental design and result for functional properties

| Trials | Frying temperature(°C) | Frying time (min) | Cowpea Proportion (%) | Bulk density (%) | Solubility (%) | Swelling Capacity (%) | Water Absorption Capacity (%) | Oil Absorption Capacity (%) |

|---|---|---|---|---|---|---|---|---|

| 1 | 134.05 | 5.22 | 76.08 | 0.46 | 8.23 | 1.8 | 183.33 | 151.67 |

| 2 | 145.95 | 5.22 | 76.08 | 0.46 | 10.13 | 2.37 | 196.67 | 161.67 |

| 3 | 134.05 | 8.78 | 76.08 | 0.46 | 9.23 | 1.7 | 196.67 | 166.67 |

| 4 | 145.95 | 8.78 | 76.08 | 0.48 | 9.77 | 2.37 | 185 | 158.33 |

| 5 | 134.05 | 5.22 | 93.92 | 0.48 | 8.97 | 2.17 | 206.67 | 170.00s |

| 6 | 145.95 | 5.22 | 93.92 | 0.46 | 9.57 | 2.37 | 205.01 | 163.33 |

| 7 | 134.05 | 8.78 | 93.92 | 0.48 | 8.70 | 1.8 | 195.00 | 161.67 |

| 8 | 145.95 | 8.781 | 93.92 | 0.46 | 9.63 | 2.37 | 210.00 | 183.33 |

| 9 | 130 | 7 | 85 | 0.46 | 9.63 | 2.43 | 211.67 | 168.33 |

| 10 | 150 | 7 | 85 | 0.48 | 9.17 | 2.3 | 183.33 | 146.67 |

| 11 | 140 | 4 | 85 | 0.46 | 8.53 | 3.23 | 213.33 | 160.00 |

| 12 | 140 | 10 | 85 | 0.46 | 8.67 | 1.27 | 171.67 | 150.00 |

| 13 | 140 | 7 | 70 | 0.46 | 7.77 | 1.53 | 183.33 | 160.00 |

| 14 | 140 | 7 | 100 | 0.48 | 9.33 | 2.13 | 206.67 | 168.33 |

| 15 | 140 | 7 | 85 | 0.48 | 8.90 | 2.07 | 196.67 | 166.67 |

| 16 | 140 | 7 | 85 | 0.46 | 9.23 | 2.17 | 201.67 | 171.67 |

| 17 | 140 | 7 | 85 | 0.48 | 9.47 | 2.03 | 195.00 | 166.67 |

| 18 | 140 | 7 | 85 | 0.48 | 10.1 | 3.37 | 186.67 | 183.33 |

| 19 | 140 | 7 | 85 | 0.48 | 9.12 | 1.73 | 178.33 | 155.00 |

| 20 | 140 | 7 | 85 | 0.46 | 8.77 | 2.27 | 191.67 | 166.67 |

TABLE 3 Coefficient of regression for functional properties

| Coefficient | Bulk density % | Solubility % | Swelling Capacity % | Water Absorption Capacity % | Oil Absorption Capacity % |

|---|---|---|---|---|---|

| Model Linear | -11.63 | -220.198 | -192.47 | 7063.72 | -2623.30 |

| X1(Frying temp) | 0.08 | -0.62 | -0.16 | -67.97 | 54.17 |

| X2(Frying time) | 0.04 | 9.60 | -1.28 | 55.996 | -6.32 |

| X3(Beans proportion) | 0.13 | 4.86 | 4.36 | -49.58 | -21.62 |

| Quadratic | |||||

| X11 | 0.00 | 701.84 | 222.13 | 0.2 | -0.26 |

| X22 | 0.00 | -0.11 | -0.01 | 0.65 | -2.85 |

| X33 | 0 | -0.01 | -0.02 | 0.18 | 395.95 |

| Interaction effect | |||||

| X1X2 | 6666.67 | -0.03 | 0.02 | -0.28 | 0.33 |

| X1X3 | 0.00 | -0.01 | 0.00 | 0.14 | 0.16 |

| X2X3 | 0.00 | 0.03 | -0.01 | -0.33 | 39640.20 |

| R2 | 0.5532 | 0.3694 | 0.3997 | 0.4841 | 0.3163 |

| F-Value | 1.38 | 0.65 | 0.74 | 1.04 | 0.51 |

However, the coefficient of regression (R2=0.37) of the quadratic model and linear were poor fit in the Table 4. Water Absorption Capacity ranged from 171.67-213.33% and there was significance difference (p<0.5) among samples. This also followed the same trend with the values reported by Abegunde et al. [5].

TABLE 4 Analysis of variance and model fitting for response parameters of maize-cowpea snack (Kokoro)

| Df | Bulk density (g/mL) | Solubility % | Swelling Capacity % | Water Absorption Capacity % | Oil Absorption Capacity % | |

|---|---|---|---|---|---|---|

| Sequential Model Sum of Squares | ||||||

| Regression | ||||||

| Linear | 3 | 0.00** | 1.46 | 1.43 | 1141.18** | 226.08* |

| Quadratic | 3 | 0.00 | 0.65* | 0.40* | 119.55 | 274.91 |

| Interaction | 3 | 0.00** | 0.33* | 0.06* | 34.38* | 34.69* |

| Residual Error | 6 | 0.00 | 2.02 | 1.61 | 353.00 | 585.49 |

| Lack of fit | ||||||

| Linear | 11 | 0.00 | 4.00** | 1.71** | 1194.97** | 1045.21** |

| Quadratic | 5 | 0.00** | 3.03 | 1.25 | 1041.03 | 735.62 |

| Interaction | 8 | 0.00** | 3.68** | 1.65** | 1160.59* | 1010.53** |

| Pure Error | 5 | 0.00 | 1.14 | 1.61 | 339.04 | 422.11 |

*Significantly different at p<0.05.

**Not significantly different at p>0.05.

Df: Degree of Freedom.

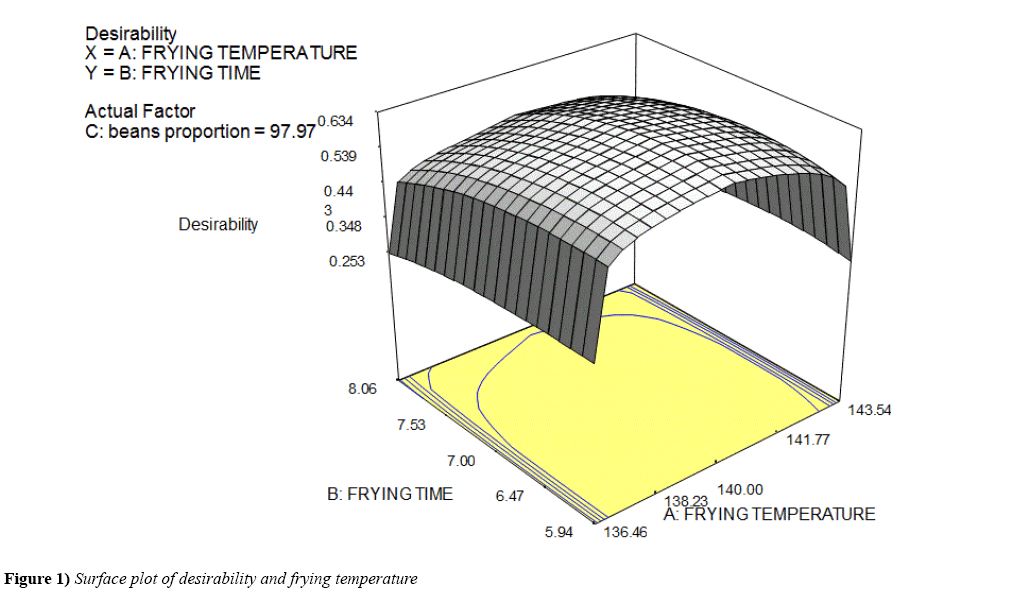

It was reported by Houssou and Ayernor [20] that cohesiveness of a product is strongly dependent on the high water absorption capacity. The water absorption capacity obtained in this work were lower compared with reported values by some researchers; Fasasi et al. [19] for fermented maize flour-tilapia mix, Adetuyi et al. [21] for malted–soya bean (280%) blend and Awoyale et al. [13] for food (kokoro) supplemented with treated (DSG) (Figure 1).

Sensory evaluation

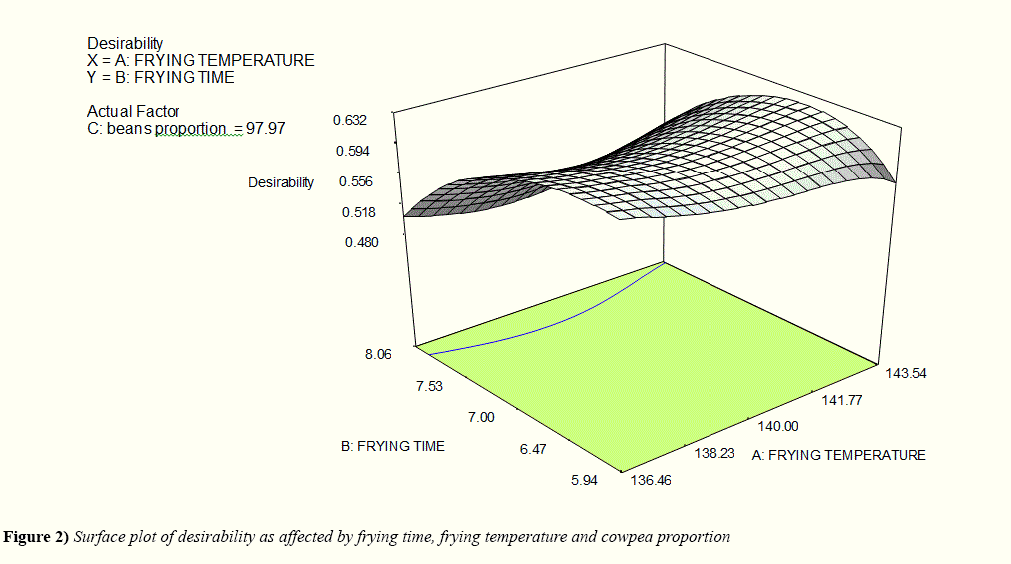

The crispiness ranged from 2-3.33 which showed significant difference (p<0.05) as shown in Table 5. Crispiness increased in frying time and frying temperature as reflected in Figure 2. The coefficient of progression R2=0.72 of the model had significant difference (p<0.01) at the linear model and also showed significant difference (p<0.01), sum of squares model showed significant difference (p<0.05) at the interaction and quadratic terms. The texture ranged from 1.93-3.33 showed significant difference (p<0.05) and overall acceptability increased by increase in frying time and frying temperature as reflected in Figure 2. However, kokoro made from 95% maize flour: 5% cowpea flour produced at frying temperature and time of 140°C and 7-8 minutes were more accepted in terms of crispness. This followed the trend reported by Awoyale et al. [13] for kokoro blended with distilled spent grains is shown on the Table 6.

TABLE 5 Experimental Design and Result for Sensory evaluation

| Frying Temperature (°C) | Frying Time (min) | Beans proportion (%) | Taste | Aroma | Texture | Overall acceptability | Colour | Crispiness |

|---|---|---|---|---|---|---|---|---|

| 134.05 | 5.22 | 76.08 | 2.47 | 2.47 | 2.93 | 2.2 | 2.33 | 3 |

| 145.95 | 5.22 | 76.08 | 2.8 | 3.07 | 2.87 | 3.27 | 3.13 | 3.27 |

| 134.05 | 8.78 | 76.08 | 2.6 | 2.27 | 2.27 | 2.13 | 2.4 | 2.6 |

| 145.95 | 8.78 | 76.08 | 2.4 | 2.27 | 2 | 1.8 | 2.73 | 2.33 |

| 134.05 | 5.22 | 93.92 | 2.6 | 2.93 | 3.07 | 2.6 | 2.6 | 2.93 |

| 145.95 | 5.22 | 93.92 | 2.67 | 2.93 | 2.93 | 2.33 | 2.47 | 2.8 |

| 134.05 | 8.78 | 93.92 | 2.4 | 3 | 2.4 | 2.13 | 2.17 | 2.13 |

| 145.95 | 8.781 | 93.92 | 3 | 2.33 | 2.6 | 2.33 | 2.73 | 2.8 |

| 130 | 7 | 85 | 2.93 | 2.73 | 3.33 | 2.8 | 2.73 | 2.87 |

| 150 | 7 | 85 | 3.13 | 3 | 3.4 | 2.47 | 2.8 | 3.33 |

| 140 | 4 | 85 | 2.47 | 2.2 | 2.4 | 2.27 | 2.4 | 2.2 |

| 140 | 10 | 85 | 2.2 | 2.27 | 1.93 | 2.27 | 2.4 | 2.27 |

| 140 | 7 | 70 | 2.33 | 2 | 2.73 | 2.6 | 2.2 | 2.53 |

| 140 | 7 | 100 | 3.07 | 2.73 | 2.73 | 2.93 | 2.6 | 2.93 |

| 140 | 7 | 85 | 2.92 | 2.73 | 2.6 | 2.6 | 3.13 | 2.47 |

| 140 | 7 | 85 | 2.93 | 2.8 | 3.07 | 2.93 | 3.13 | 3 |

| 140 | 7 | 85 | 2.27 | 3 | 2.6 | 2.27 | 2.47 | 2.87 |

| 140 | 7 | 85 | 2.73 | 3 | 2.8 | 2.87 | 2.73 | 2.73 |

| 140 | 7 | 85 | 1.53 | 1.67 | 2.13 | 1.47 | 1.93 | 2 |

| 140 | 7 | 85 | 2.07 | 2.47 | 2.13 | 2.2 | 2.53 | 2.2 |

TABLE 6 Coefficient of regression for sensory evaluation

| Coefficient | Colour | Taste | Aroma | Crispiness | Texture | Overall Acceptability |

|---|---|---|---|---|---|---|

| Model Linear | 2.58 | 2.58 | 2.59 | 2.54 | 2.56 | 2.42 |

| X1(Frying temp) | - | - | - | -5.21 | -6.27** | - |

| X2(Frying time) | - | - | - | -2.12 | -0.77 | - |

| X3(Beans proportion) | - | - | - | -2.61 | -1.51 | - |

| Quadratic | ||||||

| X11 | - | - | - | 0.02* | 0.02* | - |

| X22 | - | - | - | -0.09 | -0.15 | - |

| X33 | - | - | - | 0.00* | 0 | - |

| Interaction effect | ||||||

| X1X2 | - | - | - | 0.00* | 0.00* | - |

| X1X3 | - | - | - | 0 | 0.00* | - |

| X2X3 | - | - | - | 0.02 | 0.02 | - |

| R2 | 0.00 | 0.00 | 0.00 | 0.50 | 0.72 | 0.00 |

| F-Value | 0.32 | 0.32 | 0.49 | 1.1 | 2.87 | 0.47 |

The significant level are: *means p<0.1, **means p<0.01.

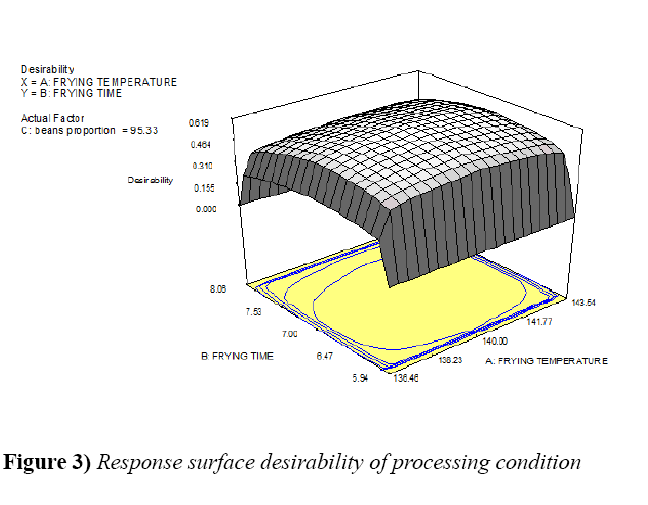

The desirability functions of RSM were used to determine the optimum processing conditions of maize snack (kokoro). Optimization was based on the desirability function; D=(d1×d2×d3×……dn) 1/n. where d1 are the desirability indices for each response (d1=1; most desirable and d1=0; least desirable) and n is the number of response used. In this process, responses that have different scaling are transformed into one measurement useful in predicting the process [22]. The responses were used as the control parameters, used for determining the optimum quality characteristic with respect to frying temperature, frying time and quantity of beans proportion and this as shown in Figures 1 and 2, respectively. When frying time was set as target, the optimum processing conditions (frying temperature, frying time, beans proportion) were 140°C, 6.43-6.44 min and 97.93-97.97%, respectively while optimum functional properties (bulk density, swelling capacity, solubility, water absorption capacity, oil absorption capacity) were 0.48 g/mL, 2.38-2.39%, 9.26%, 203.7-203.8% and 170.9-171%, respectively. Also, for optimum sensory evaluation (taste, aroma, texture, overall acceptability, colour and crispiness) were 2.58, 2.59, 2.71, 2.42, 2.58 and 2.64 respectively. The desirability (0.63) was obtained for this work. When frying time was set at range, the frying temperature was set at target and beans proportion was in range, the optimum processing conditions (frying temperature, frying time, beans proportion) were 136.46-143.54°C, 7 minutes and 97.86-97.97 %, respectively while optimum functional properties (bulk density, swelling capacity, solubility, water absorption capacity, oil absorption capacity) were 0.47-0.48 g/mL, 2.18-2.33%, 9.18-9.53%, 201.24-201.69%, and 168.05-170.15%, respectively. Also for optimum sensory evaluation (taste, aroma, texture, overall acceptability, colour and crispiness) were 2.58, 2.60, 2.88-2.96, 2.42, 2.58 and 2.67-2.99, respectively and the desirability (0.64) was obtained for this work.

When all the processing conditions were set at range, the predicted processing conditions (frying temperature, frying time, beans proportion) in the Figures 1 and 2 were 136.46–143.54°C, 6.04–6.73 minutes and 97.78–97.96% respectively while optimum functional properties (bulk density, swelling capacity, solubility, water absorption capacity, oil absorption capacity) were 0.47-0.48 g/mL, 2.32-2.50%, 9.01-9.56%, 203.64-209.15% and 166.12-169.03%, respectively. Also for optimum sensory evaluation (taste, aroma, texture, overall acceptability, colour and crispiness) were 2.58, 2.59, 2.92-2.99, 2.42, 2.58 and 2.69-3.00, respectively and the (0.64) was obtained for this work.

The point with highest possible desirability (0.64) function that could be taken as the optimum condition for frying temperature and frying time combination of maize snack (kokoro) was found to be 143.54°C and 7 minutes, respectively as shown in Figure 3.

Conclusion

Frying of maize snack (kokoro) at different temperature and time with the combination of beans in different proportions affected the general properties of kokoro. The Fortification of maize snack (kokoro) has strong tendency to improve its nutritional content however, have effect on the functional properties. the Predicted frying temperature, time and beans proportion of 143.5°C, 7 minutes and 98%, respectively with the functional properties 0.47 g/mL (bulk density), 2.3%(swelling capacity), 9.5% (solubility), 201.7% (water absorption capacity), 2.58 (taste), 2.60(aroma), 2.88-2.96 (texture), 2.42 (overall acceptability), 2.58 (colour) and 2.67-2.99 (crispiness) gave the highest desirability value.

REFERENCES

- Uzo Peters PI, Arisa NU, Lawrence CO, et al. Effect of Partially Defatted Soybeans or groundnut cake on Proximate and Sensory characteristics of Kokoro. African Journal of Food Science.2008;2:98-101.

- Rosa N, Chavez-jauregui RAC, Marian EM, et al. Acceptability of snacks produced by the extrusion of Amaranth and blends of chicken pea and bovine lung. International Journal of Food Science and Technology.2003;38:795-98.

- Idowu AO, Aworh OC. Optimization of some processing conditions for Kokoro production using Response Surface Methodology. Agric Eng Int: CIGR Journal. 2014;16:187-95.

- Ayinde FA, Bolaji OT, Abdul-Salaam RB, et al. Functional properties and quality evaluation of kokoro blended with beniseed cake (Sesame indicum). African Journal of Food Science. 2012;6:117-23.

- Abegunde TA, Bolaji OT, Adeyemo TB. Quality Evaluation of Maize Chips (kokoro) Fortified with Cowpea Flour. Nigerian food journal. 2014; 32:97-104.

- Lui-Ping F, Min T, Gong-nian X, et al. International Journal of Food Science and Technology. 2005;40:39-46.

- Sobukola OP, Awonirin SO, Sanni LO, et al. Deep fat frying of Yam slices: Optimization of Processing Conditions using response surface methodology. Journal of Food Processing and Preservation. 2008;32:343-60.

- Patterson SP, Philips RD, McWatters KH, et al. Fat Reduction affects Quality of Akara (Fried Cowpea Paste). International Journal of Food Science and Technology. 2004;39: 681-93.

- Akinoso R, Aboaba SA, Olajide WO. Optimization of Roasting temperature and time during Oil extraction from Orange (Citrus sinesis) seeds: A response Surface Methodology Approach. African Journal of Food, Agriculture, Nutrition and Development. 2011;11:5300-17.

- Sulaeman A, Keeler L, Giraud DW, et al. Carotenoid content and Physicochemical and Sensory characteristics of Carrot chips deep fried in different oils at several temperatures. Journal of Food Science. 2001;66:1257-64.

- Garayo J, Moreira R. Vacuum Frying of Potato chips. Journal of Food Engineering. 2002;55:181-91.

- Quoe LPT, Xinh NTK, Nguyet HTK, et al. Application of response surface methodology (RSM) in condition optimization for essential oil production from Citrus latifolia. Emirate Journal Food and Agriculture. 2012;24:25-30.

- Awoyale W, Maziya-Dixon B, Sanni LO, et al. Nutritional and sensory properties of a maize-based snack food (kokoro) supplemented with treated Distillers’ spent grain (DSG). International Journal of Food Science and Technology. 2011;46:1609-20.

- Olapade AA, Okafor GI, Ozumba AU, et al. Characterization of common Nigerian cowpea (Vigna unguiculata L) varieties. Journal of Food Engineering. 2002;55:101-3.

- Narayana M, Narasinga S. Effect of partial proteolysis on the functional properties of winged bean (Phorsphocarpustetragonolobus) flour. Journal of Food Science. 1984;49:944-47.

- Leach HW, McCowen LD, Scoch TJ. Structure of starch granule Swelling and solubility patterns of various starches. Cereal Chemistry. 1959; 36:534-44.

- Beuchat LR. Functional and electrophoretic characteristic of succinylated peanut flour Protein. Journal of Agricultural and Food Chem-istry. 1977;25:258-61.

- Shamaei S, Emam-djomeh Z, Moini S. Modelling and Optimization of Ultrasound Assisted Osmotic Dehydration of Cranberry Using Response Surface Methodology. J. Agric. Tech. 2012;14:1523-34.

- Fasasi OS, Adeyemi IA, Fagbenro OA. Functional and Pasting Characteristics of Fermented Maize and Nile Tilapia (Oreochromis niloticus) Flour Diet. Pakistan Journalof Nutrition. 2007;6:304-9.

- Houssou P, Ayernor GS. Appropriate processing and Food functional properties of Maize flour. African Journal of Science and Technology, Science and Engineering Series. 2002;3:126-31.

- Adetuyi FO, Badejo OF, Ikujenlola AV, et al. Storage influence on the functional properties of malted and unmalted maize (Zea mays L ssp mays) and soybean (Glycine max L Merrill) flour blends. African Journal of Food Science. 2009;3:56-60.

- Singh RP. Moving boundaries in Food Engineering. Food Technology. 2000;54:20-45.