Sign up for email alert when new content gets added: Sign up

Abstract

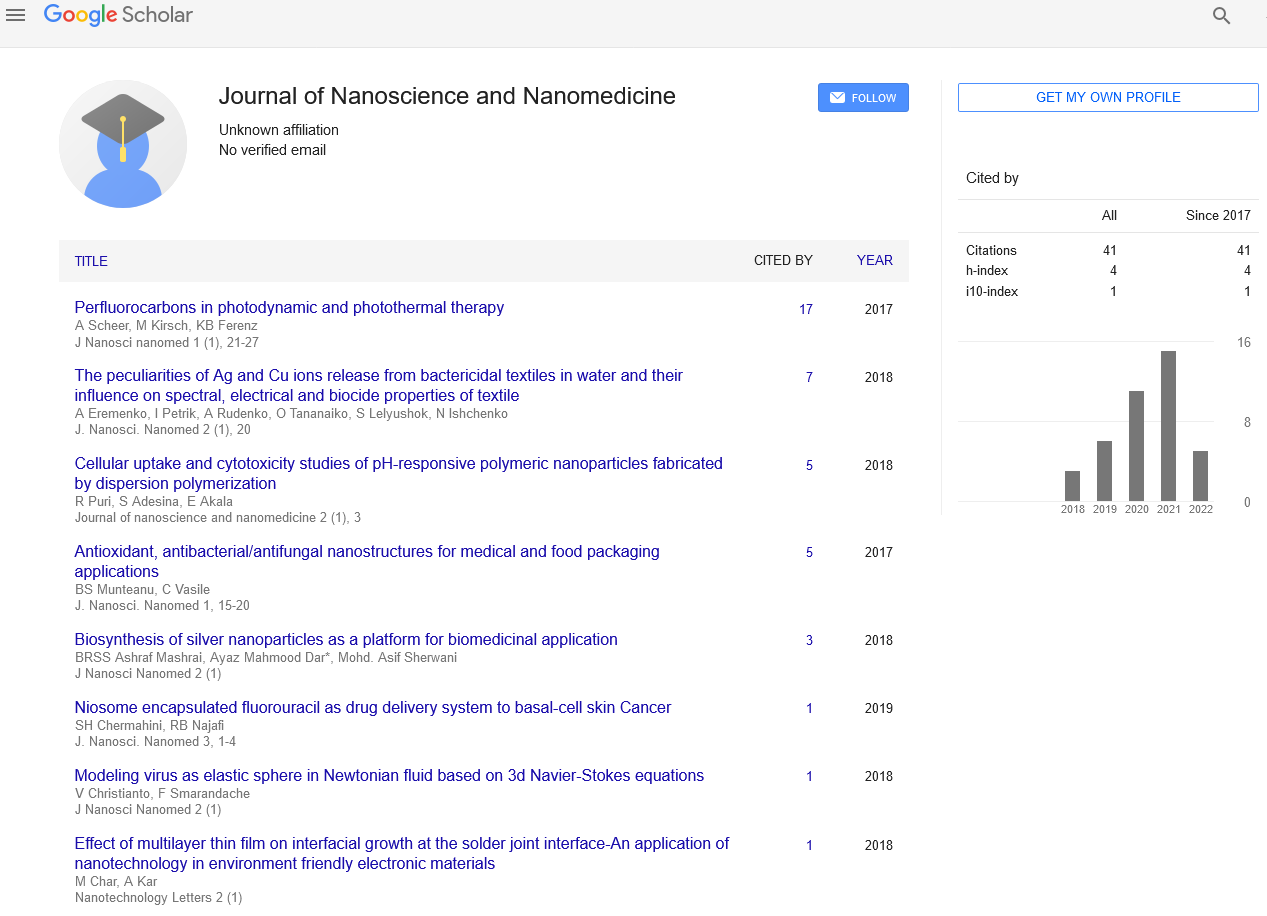

A facile composite-hydroxide-mediated route for preparation of composite Fe3+-NiO nanostructures

Author(s): Arfan M, Shahid T, Khan MZ, Qamar Z, Javed A, Taj M Khan*, Tayyaba BiBi and Hussain BA viable composite-hydroxide-mediated (CHM) method was used to prepare nickel oxide (NiO) nanostructures. Composites of iron(III)-nickel oxide (Fe3+-NiO) nanostructures were obtained using 5%-15% Fe3+ during the synthesis process. NiO and Fe3+-doped NiO composite formations were monitored via X-ray diffraction, Fourier transform infrared spectroscopy (FTIR), scanning electron microscopy, energy dispersive Xray spectroscopy (EDS), and ultraviolet-visible (UV-Vis) spectroscopy. For the proposed range, pure NiO was obtained with octahedral peculiarities. With increased Fe3+ content, the octahedron feature was transformed into new morphologies; the morphological change was significant, given the short reaction time. EDS confirmed the presence of Ni and O elements, and FTIR resolved a strong signature associated with Ni-O bonding. The bandgap of NiO, estimated from UV-Vis measurements, was in the range 1.73-5.68 eV, depending on the Fe3+ doping concentration. For the proposed processing temperature and reaction time, the CHM method shows great potential as an easy nanomaterial preparation procedure for research purposes.

Full-Text | PDF